Comprehensive Thermoforming Services

For more than 50 years, we have been translating our customers’ ideas into thermoformed realities. From serving as a partner through the product discovery and need identification phase to a provider of in-house mold fabrication and custom graphic design for customized finishes, we are proud to deliver precision-crafted products with customer-focused service.

Our engineers bring innovation and ingenuity to each project, sitting with customers to develop concepts from initial sketches to detailed CAD drawings, customized mold creation, and final production. Learn More

Our in-house mold shop with industrial 3D printers provide access to immediate mold making, resulting in a streamlined build process that gets our customers’ products to market with precision and efficiency. Learn More

Duo-Form is a one-stop shop for custom designed parts and pieces, specializing in thick sheet thermoforming ranging between .030 inches to .500 inches and large sheet capability up to 140 inches x 108 inches. Learn More

Duo-Form is a one-stop shop for custom designed parts and pieces, offering assembly and custom packing capabilities, allowing us to provide you with beautiful finished products that are ready to go. Learn More

Duo-Form is dedicated to providing exceptional customer service alongside continuous innovation and ingenuity. Through our internal efforts to support an inclusive culture, teamwork, and continuous growth, our customers enjoy productive partnerships that revolve around common goals and transparent processes.

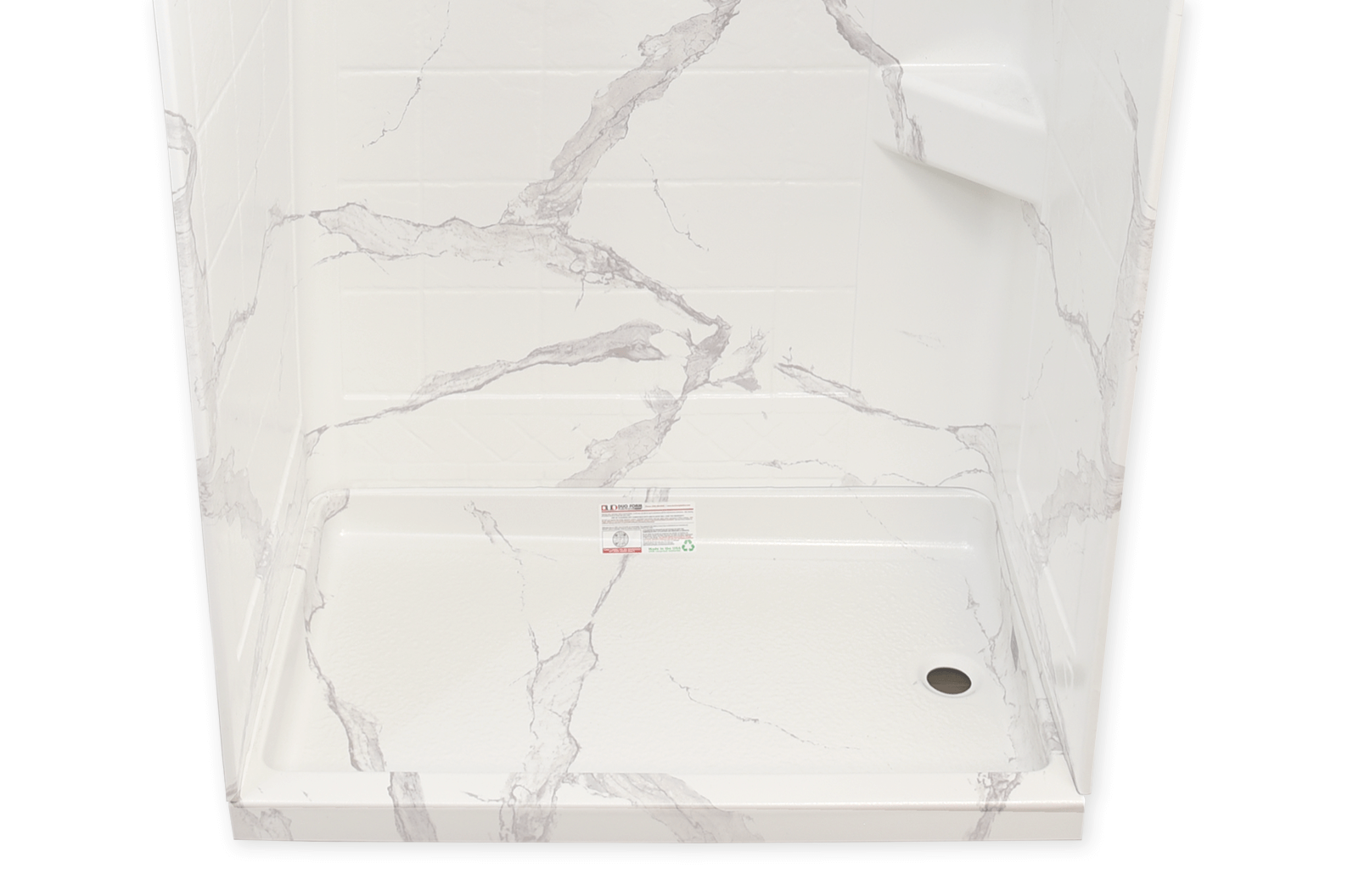

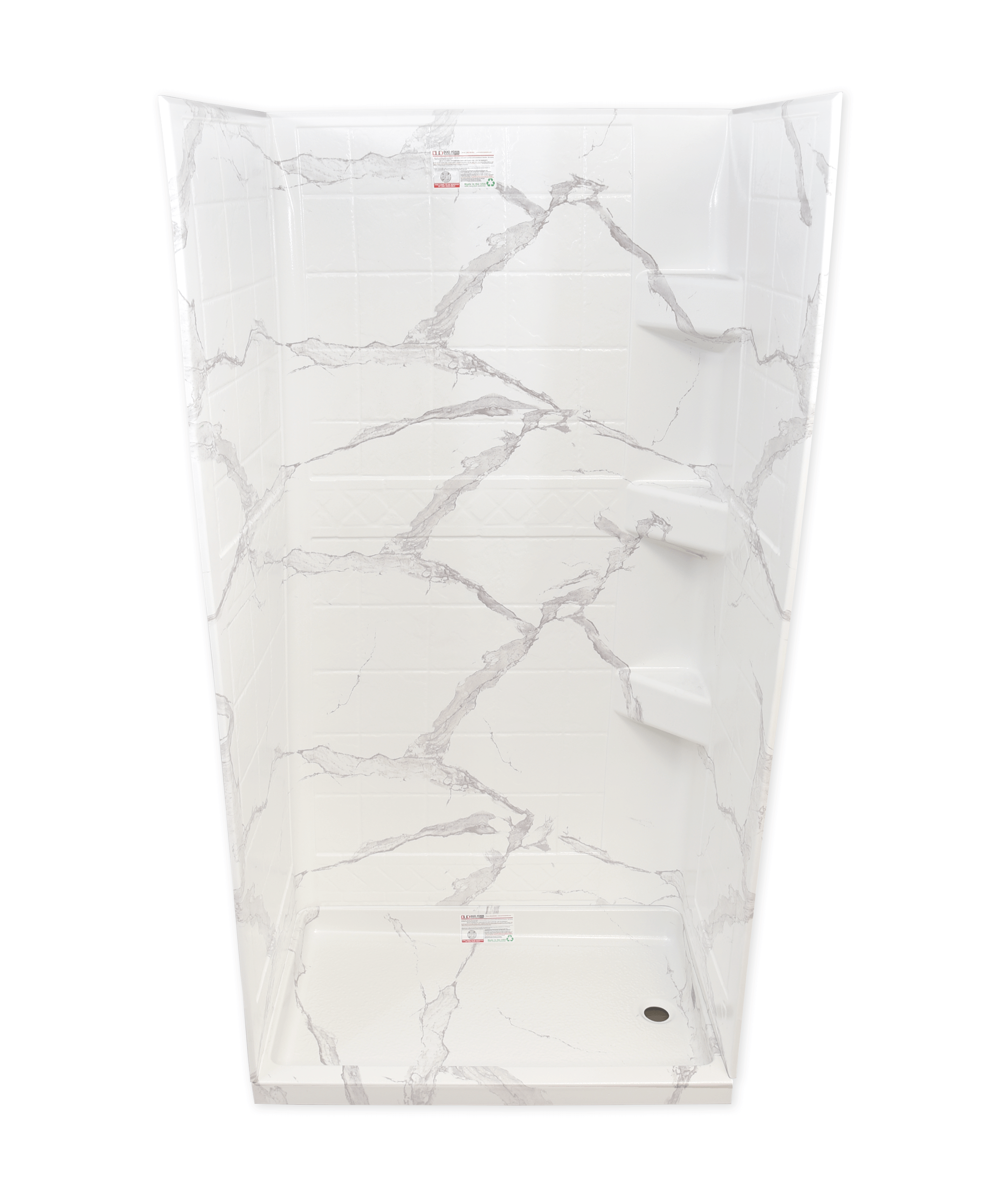

NEW DUO DESIGNER SHOWER PAN – MYTHIC

244022293-1

Our most-trusted shower pans now with new designer high-end prints. Upgrade your RV bath today!

Designer Printed Shower Pans- Upgrade the look & feel of your RV bath with a complete residential look.

Duo Shower Pans have been trusted by RV manufacturers for 50+ years....

View Details

DUO Protects: ADULT Face Shield Combo Kit includes Face Shield and Bag

For the first time ever, we are offering an Adult Face Shield and Face Shield Bag Combo Kit for a new lower price.

DUO Safety Shield offers full-visibility while acting as a facial barrier and guard from potential bodily fluids, contamination and effectively deters user from touching eyes, nose and mouth.

DUO STANDARD ADULT FACE SHIELD: 8.75” Tall x 7.5” Wide

Entering 2024 with a Brand NEW DUO Design Center Continuing on their path of dedication...

Read More

DUO-FORM Takes Home Two Society of Plastics Engineers Awards (Cleveland, OH) The Society of Plastics...

Read More

Thermoforming company turns to 3D printing for molds Duo-Form finds extrusion 3D printer goes beyond...

Read More

Edwardsburg, MI- November 11, 2022 Duo-Form has been honored with statewide recognition with the 2022...

Read More

Edwardsburg, MI‐ October 14, 2022 Duo-Form is receiving statewide recognition as a Top Three Finalist...

Read More

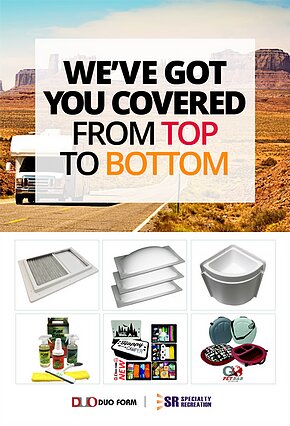

Edwardsburg, MI- October 1, 2021 Duo-Form is pleased to announce Specialty Recreation, Inc. as their...

Read More

© Duo-Form . All rights reserved.